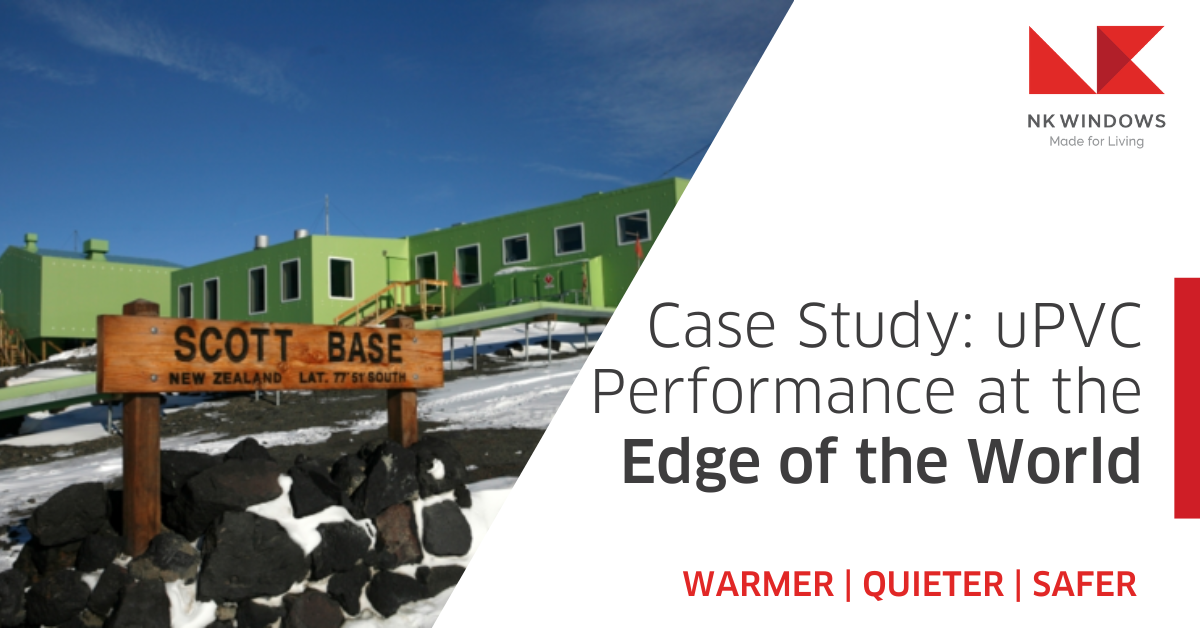

When you choose windows for your home, you want warmth, reliability, and comfort you can trust. At Scott Base in Antarctica, those needs become critical for survival.

For almost 15 years, our team at NK Windows has supplied custom uPVC window and door systems to this remote research station. The same technology that keeps your home comfortable has proven itself in one of the toughest climates on earth.

This project gave us a rare opportunity to show what high-quality uPVC can do when the pressure is at its highest. Every window we built had to protect people working in temperatures that can fall toward minus 50 degrees Celsius. The stakes were simple. The windows had to perform perfectly.

The Requirements

Scott Base engineers needed window systems that could achieve four things.

Hold stable indoor temperatures in extreme cold.

Antarctica steals heat faster than almost anywhere on the planet. Poorly insulated windows would put people and equipment at risk.

Stand firm against violent winds.

Gusts can reach speeds that test every part of a building. Frames must resist twisting and flexing while keeping seals tight.

Support sensitive scientific work.

Some buildings house instruments that cannot be near metal. Even a small amount of interference could compromise years of research.

Deliver absolute reliability.

Repairs are possible only during a short summer window. Every unit needed to arrive fully finished, fully tested, and ready to perform from the moment it was installed.

The challenge was clear. Create window systems that could survive a place designed to push materials to breaking point.

Our Solution

We approached the project with the same mindset we bring to your home. Listen first. Understand what matters. Then design for real world performance.

High performance uPVC profiles

We used aluplast’s multi chambered uPVC frames because they trap layers of still air inside the profile. This creates an incredibly effective thermal barrier. It is the same reason homeowners feel warmer with our windows, and it becomes even more valuable when the outside temperature drops far below freezing.

Tailored solutions for unique scientific needs

One research hut required zero metal components. To meet this requirement, we designed a completely non-metallic uPVC system that delivered the insulation and stability the scientists needed without affecting their equipment.

This level of customisation shows the flexibility of uPVC and our willingness to solve problems that others may walk away from.

Structural strength for high wind zones

Every frame was reinforced where required, every seal tested repeatedly, and every detail checked before shipping. uPVC performs exceptionally well under stress because it does not warp, expand, or contract in the way many traditional materials do. This stability is essential when buildings face constant pressure from Antarctic winds.

Precision manufacturing in Christchurch

All units were built and signed off before leaving our factory. Nothing could rely on on-site adjustments. The reliability of uPVC combined with careful workmanship reduced the risk of failure and gave the installation team complete confidence.

What We Achieved

The uPVC systems we supplied have continued to perform through years of freezing temperatures and high winds, protecting both people and the sensitive equipment they rely on.

What stands out most is the consistency. The windows do their job quietly and without fuss. They hold warmth inside. They keep the storm outside. They stay stable even when the temperature swings dramatically from one day to the next. This steady performance shows how trustworthy uPVC is when the conditions are demanding.

This project highlights the strength of well-designed uPVC in extreme environments. Its long-term stability at Scott Base gives homeowners confidence that the same technology will deliver lasting comfort and performance in New Zealand’s climate.